Q. Why there are needs for Water system Validation? Ans: It is vital that the quality of water should be distinct for item excellent. Minimal good quality of water may lead to merchandise degradation, contamination, loss of products, and financial gain.

In combination with the ways outlined for PW system validation, WFI system validation involves an extra focus on the generation and control of substantial-top quality water Conference the precise prerequisites for WFI. The validation approach usually will involve thorough screening and documentation of the different levels, for instance pretreatment, distillation, or other validated approaches employed for WFI generation.

All those techniques of water use can drastically contaminate pristine water in a water system when it exits, to ensure that “terrible” water is delivered to a production Procedure. Should you sample the water in a different way (improved) than it's used by manufacturing, you will get lessen (greater) micro counts that aren't representative with the water high quality that is in fact be used. Sampling like production water use for QC release is necessary by FDA to become similar. If It's not, this could generate you an FDA483 observation or worse.

Qualification functions wherein locations have to be recognized for placement of data logger or sensors, then schematic layouts to depicts the placement of sensors or place identification shall be laid out in the Qualification/validation protocol for better clarity.

Using the more proven way of distillation, this functions by turning water from a liquid to the vapour and after that from vapour again to liquid. Endotoxin is eliminated from the swift boiling which causes the water molecules to evaporate and also the fairly larger endotoxin intricate molecules to remain guiding.

This may transpire with bad upkeep of pretreatment unit ops for instance carbon beds, and likewise when coincident with high endotoxin amounts in the town water every time they change about to straight chlorine from chloramine for the Section of a year.

Should the sampling is for QC “launch” on the water for manufacturing use, then the outlet utilized by production must be sampled in EXACTLY the same trend as it really is employed by manufacturing – exact outlet sanitization (if any), similar manufacturing hose (Irrespective of how grungy or inadequately maintained), same pre-flushing (if any), exact every thing. The goal of the sample data should be to copy the identical excellent of water that producing is employing, so You should duplicate in sample collection how the water is drawn from your system for use.

General performance Qualification of equipment shall be well prepared depending on the consumer’s need and design and style qualification/technological specification, furnished by the manufacturer.

Requalification is necessary if there are important changes or modifications during the system that influence the qualification point out or if you can find excursions impacting excellent.

18. If I do not have a water microbial specification but only an Alert and Action Level, is there a microbial level looked upon as unfit for click here use?

a regular news company to maintain you up-to-date on new developments in GMP and affiliated restrictions.

ANSBACH, Germany — German engineers switched on a water treatment system at U.S. Military Garrison Ansbach this week to begin the lengthy-prepared purge of harmful PFAS chemical substances from groundwater exiting The bottom.

A perfectly-devised QPP, that has been agreed on and signed by equally functions, will save time and makes it simpler to finish routines which include structure, installations and assessments. An interface settlement also needs to be issued early within the project and may clarify particulars pertaining to tie-in details, Handle system interfaces and media.

Problems with endotoxin challenges in check here relation to reverse osmosis are central to a different European Medicines Company assistance paper regarding pharmaceutical water production. This information considers The main element messages throughout the direction as well as vital learning points in relation to contamination control.

Richard "Little Hercules" Sandrak Then & Now!

Richard "Little Hercules" Sandrak Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Judge Reinhold Then & Now!

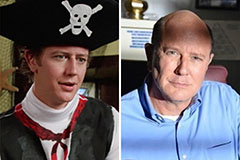

Judge Reinhold Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now!